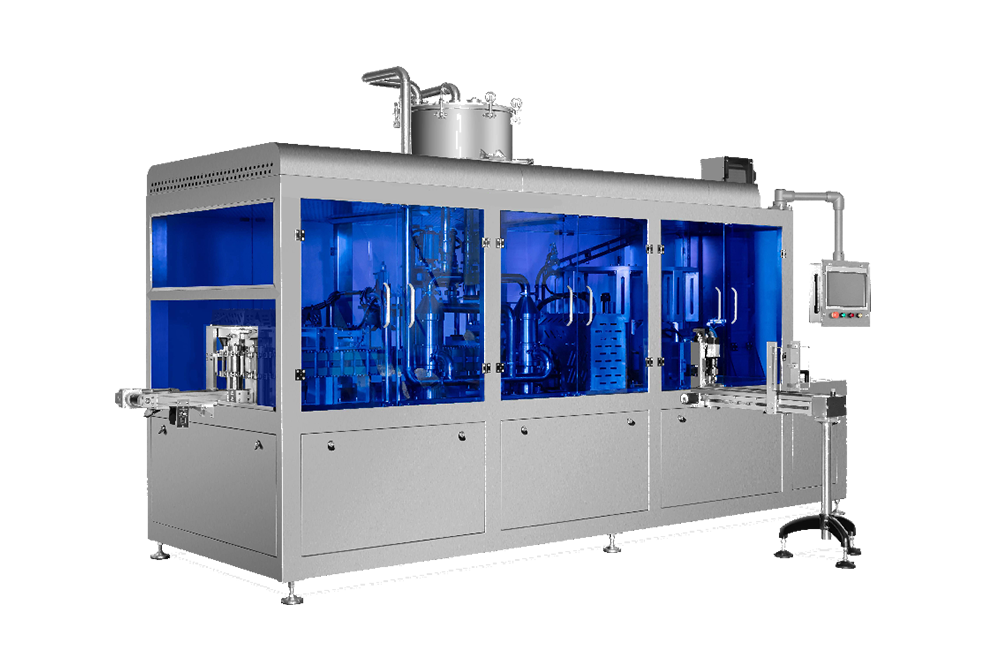

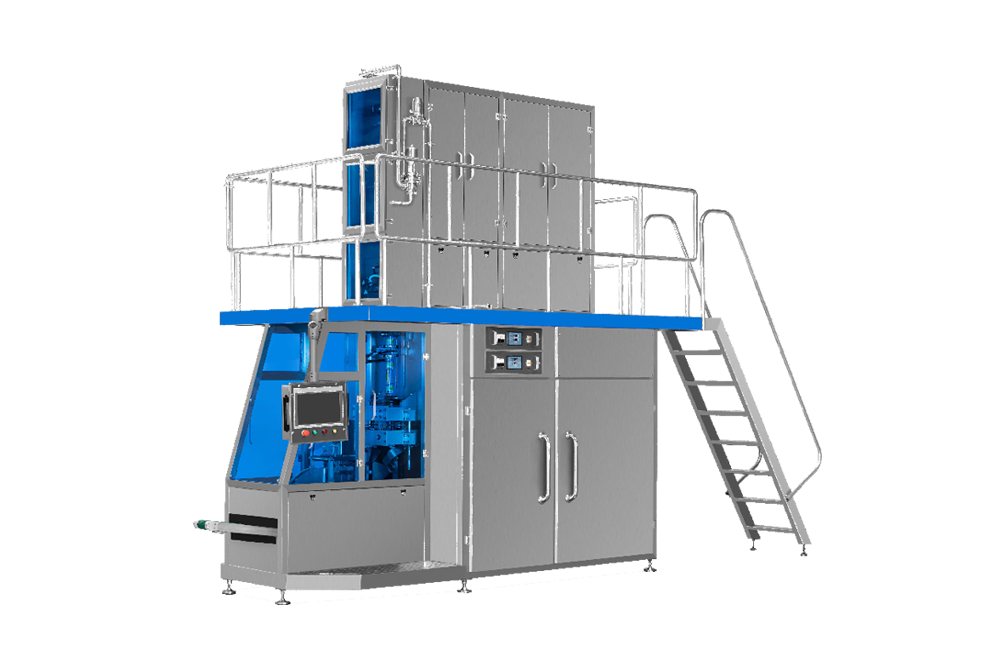

Specifications

LFS(Liquid Food Solution) is dedicated to be a global comprehensive liquid food packaging provider.

- Capacity

3600 p/h

- Power source

380 V, 3 Phases, 50 HZ

- Power Consumption

< 4 kW

- Compressed Air

Pressure: 600 Kbar; Consumption: 2 m³/min

- PLC

Trio (UK)

- Servo Joint Drive

Estun (China)

- Control Panel

Kunlun Tongtai (China)

- Pneumatic Component

SMC (Japan)

- Sliding Joint

HIWIN (Taiwan,China)

- Sensor

SICK (Germany)

- Power Supply

MEANWELL (Taiwan,China)

- Hotmelt Component

Robatech (Swiss)

- Net Weight

800 kg

- Dimensions

1850×1800×1900mm(L×W×H)

Product Advantages

LFS(Liquid Food Solution) is dedicated to be a global comprehensive liquid food packaging provider.