| Core Advantages of Flexible Chain Conveying Line: Why Has It Become a Popular Choice in the Industry?

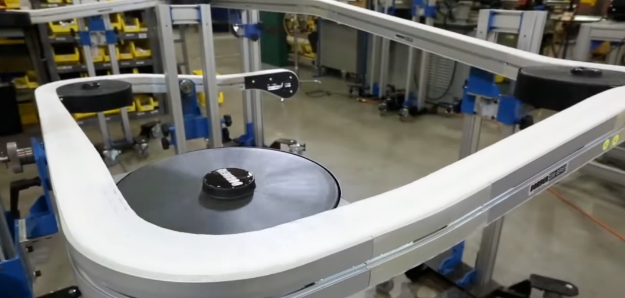

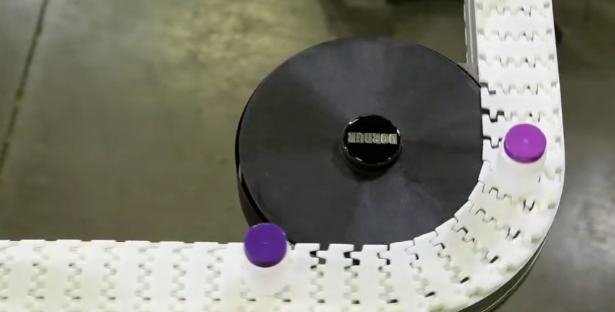

The flexible chain conveying line is composed of high-strength engineering plastic chain links and modular accessories. Its unique design endows it with four core capabilities:

- Flexible and adaptable: supports multi-dimensional layouts such as horizontal, vertical, bending, and spiral, and can easily adapt to complex spaces;

- Clean and safe: free of oil stains and corrosion, meeting high hygiene standards in industries such as food and medicine;

- Efficient and low-consumption: modular design enables quick disassembly and assembly, reducing maintenance costs by over 30%;

- Intelligent compatibility: seamlessly connects with robotic arms and visual inspection systems, facilitating digital upgrades.

| In-depth Analysis of Six Scenarios: How Does the Flexible Chain Conveying Line Empower Various Industries?

1. Food and Beverage Industry: Safeguarding "Safety on the Tongue"

- Scene Pain Points: Traditional metal conveyors are prone to bacterial growth and have many cleaning blind spots.

- Flexible Solution: Uses food-grade materials, certified by the US FDA and EU EU; supports high-pressure water gun rinsing, completing the entire line cleaning and disinfection in 2 hours; Case: A dairy company utilized the flexible chain conveying line to achieve full-process automation for yogurt filling, packaging, and palletizing, reducing product defect rates by 60%.

2. Pharmaceutical Production: The "Invisible Guardian" of Sterile Environments

- Scene Pain Points: Pharmaceutical packaging requires absolute cleanliness, while traditional equipment is prone to dust generation.

- Flexible Solution: Anti-static design to avoid drug powder adsorption; closed conveyor channels + online cleaning system to meet GMP certification requirements; Case: A vaccine production enterprise achieved zero-contact transfer of ampoule bottles using the flexible chain conveying line, reducing cross-contamination risks by 90%.

3. E-commerce Logistics: Solving the "Overstocking" Problem

- Scene Pain Points: Fluctuating order volumes, traditional sorting lines have poor scalability.

- Flexible Solution: Can be easily added or reduced as needed to cope with peak traffic periods such as "Double 11"; combined with RFID scanners for intelligent package diversion; Case: A leading e-commerce warehouse equipped with the flexible chain sorting system, handling over 500,000 packages per day, saving 40% in labor costs.

4. Automotive Manufacturing: The "Flexible Partner" for Precise Assembly

- Scene Pain Points: Numerous types of components, traditional conveyors take a long time to change models.

- Flexible Solution: Through quick-change tooling fixtures, 15 minutes to switch production models; integrated force control sensors to ensure precise components are transported without damage; Case: A new energy vehicle manufacturer achieved a 35% increase in mixed-line production efficiency after applying the flexible chain conveying line.

5. Electronic Manufacturing: The "Clean Protector" for Chip-level Cleanliness

- Scene Pain Points: Electronic components are sensitive to static electricity, traditional equipment is prone to damage.

- Flexible Solution: Anti-static chain plates + ion wind cleaning devices, cleanliness up to Class 1000; micro vibration suppression design to ensure zero vibration during chip transportation; Case: A semiconductor factory introduced the flexible chain line and saw a 99.98% increase in chip yield.

6.Daily Chemical Packaging: The "Backstage Driver" of Economical Appearance

- Scene Pain Points: Various cosmetic bottle shapes, traditional conveyors are prone to scratching the surface.

- Flexible Solution: Customized soft chain plates to avoid damage to glass/acrylic packaging; equipped with visual inspection systems to remove defective products in real time; Case: A high-end cosmetics brand utilized the flexible chain line for automated packaging of lipsticks, doubling production capacity.

| Future Trends: The "Intelligent Evolution" of Flexible Chain Conveying Lines

With the deepening of Industry 4.0, flexible chain conveying lines are deeply integrating with technologies such as AI and digital twins:

- Predictive Maintenance: Through vibration sensors + big data analysis, early warning of faults;

- Digital Twin: Virtual debugging technology improves production line layout efficiency by 50%;

- Green Manufacturing: Recyclable materials account for over 80%, and carbon emissions are reduced by 25%.

| Conclusion: Flexibility enables production to have unlimited possibilities.

From standardization to individualization, from fixed production lines to dynamic reconfiguration, flexible conveyor lines are redefining the boundaries of industrial transportation.

It is not only the "connector" of the production line, but also the "strategic weapon" for enterprises to respond to market changes.

In the future, whoever can seize the initiative in the flexibleization race will gain the initiative in the new battlefield of intelligent manufacturing.