Project Feature:

☑Customization ☑Flexibility □Integration □Empowerment □Cost-Efficiency Optimization

Project Background & Requirements:

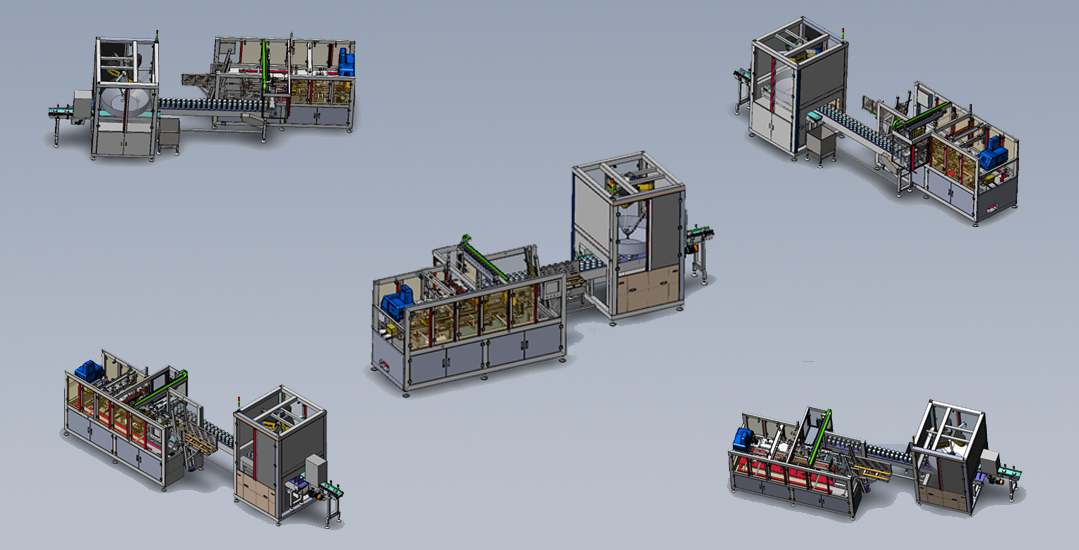

A major dairy producer needs automation of the end‑of‑line packaging for its processed‑cheese cups. Manual packing limited throughput and often produced orientation errors when different lid geometries were run. The customer therefore tendered for a fully automatic wrap‑around case‑packer.

Project Solution:

To meet these requirements, we engineered a custom wrap-around case packing system tailored for the requirement.

1. Robot & Visual Stacking System classify each incoming cup by lid shape and lid orientation in real time.

2. Automatic Cardboard Packaging Machine

The frame of our equipment is made of carbon steel, while the parts in contact with the product are made of 304 stainless steel.

▶ Product introduction:

Fully automatic one-piece carton wrapped charter plane is also called open loading and sealing machine. Is our company on the basis of advanced technology, independent research and development of new high-speed automation packaging equipment. The structure of the equipment is reasonable: the product is divided into multiple lines by the partition on the feed conveying line, after the product is grouped, and falls on the board through the packing mechanism. In the process of the falling mechanism with the product and cardboard, the cardboard is folded into a carton through a component baffle. In the main drive belt of the carton forward at the same time, complete automatic spray, unpacking, molding and other processes.

▶ Structure:

It is composed of import conveying part, product lane whole part, suction carton part, folding molding part, spray glue bonding part, pneumatic part and electronic control part, and export conveying part.

▶ Features:

The traditional preset carton packing, change the slice carton packing, save the carton cost, completed by the machine structure action from the chip carton to product packing automatic molding for complete carton process, instead of the traditional unpacking, packing, sealing link, one pace reachs the designated position of product automation packaging, make production more efficient and more economical.

▶ Working principle:

According to the packaging requirements, the product feeding, and the feeding board mechanism sends the carton to the carton by the pneumatic part, and the final complete carton packaging of the product is synchronized by several servo motors and mechanical adjustment to ensure the accurate, qualified and beautiful packaging of each group of products.

▶ Machine Mechanical. Efficiency(MME): 98%

▶ Dimension: 8150*2000

3. On-Line Weigh Rejector

The weight selection machine is specially designed for the high precision requirements, high stability and intelligent detection technology of the packaging weight, and has the core invention patent. Select famous brand components and integrated circuits, using high-precision CNC structure design, with patented weighing algorithm and other advanced technologies, to achieve industry-leading detection performance.

▶ Famous brand accessories used

1. HBM original gravity sensor

2. Danfoss, Frequency converter

3. 7-inch industrial touch screen for Siemens

4. Wynn high wear-resistance conveyor belt

5. Japan Omron Sensors

6. Festo Pneumatic components

7. Schneider Electric components

8. High-precision CNC scale plate structure components

9. All-stainless steel 304 rack

▶ Advanced technology design adopted

1. Original ultra-high-speed weight sensor, excellent frequency response;

2. FPGA hardware filter with intelligent algorithm, excellent weighing processing speed;

3. Intelligent self-learning technology, fully automatic setting of weighing parameters, simple setting;

4. Ultra-fast dynamic weight tracking and automatic compensation technology, effectively improve the detection stability;

5. Friendly operation interface based on full touch screen, easy to operate;

6. 40 product presets, easy product editing and switching;

7. Large-capacity sorting log, with data output traceability function;

8. Structural components of CNC processing, excellent dynamic stability;

9. High quality stainless steel 304 rack, strong and durable.

Project Outcome:

Our tailored design won the tender ahead of multiple international competitors. The line was under production.

The project showcases our ability to integrate robotics, vision, and wrap‑around technology into a single hygienic platform, delivering both flexibility and performance for today’s multi‑SKU production lines in a tailor-made approach.