Project Feature:

☑Customization □Flexibility ☑Integration □Empowerment □Cost-Efficiency Optimization

Project Background & Requirements:

This client, one of the three milk product manufacturers in Belarus, required an integrative solution for , of which the Belarus providing civil engineering jobs, LFS’s Russian partner providing automation service, while LFS providing a series of high quality made-in-China equipment on time.

Project Solution:

LFS provided the following equipment and solutions for the client:

▶ UHT Unit

ü Automatic Heat Treatment Unit for dairy products based on tubular heat exchanger, Capacity: 4500/7500 l/h

ü Deaerator

ü Aseptic Homogenizer

▶ Aseptic Tank

ü Aseptic vessel 12 000 l, made from AISI 316L, with cooling jacket, ladder and service platform, magnetic agitator and cleaning spray balls

ü Oil-free compressor with receiver

▶ CIP Station

ü 3 - line CIP station, capacity 30 000 l/h each line

▶ Transportation

ü Delivery on DAP Belarus, Rogachev, Incoterms 2020

▶ Services

ü Project Management

ü Process engineering

ü Installation works within the scope of supply

ü Commissioning works and Perfomance Validation works

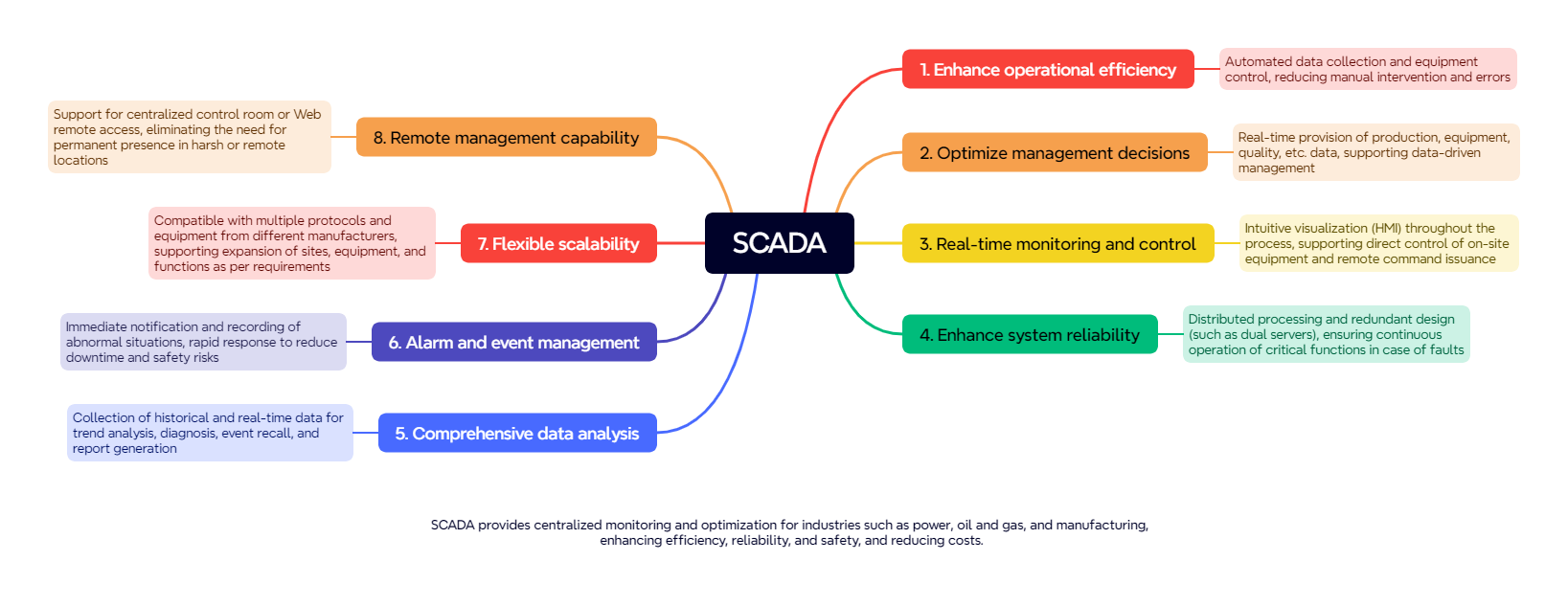

ü Software development and delivery of SCADA system with IT equipment

ü Operators training

Project Outcome:

The project has been delivered and the equipment installation is complete.