Project Feature:

☑Customization □Flexibility □Integration □Empowerment □Cost-Efficiency Optimization

Project Background & Requirements:

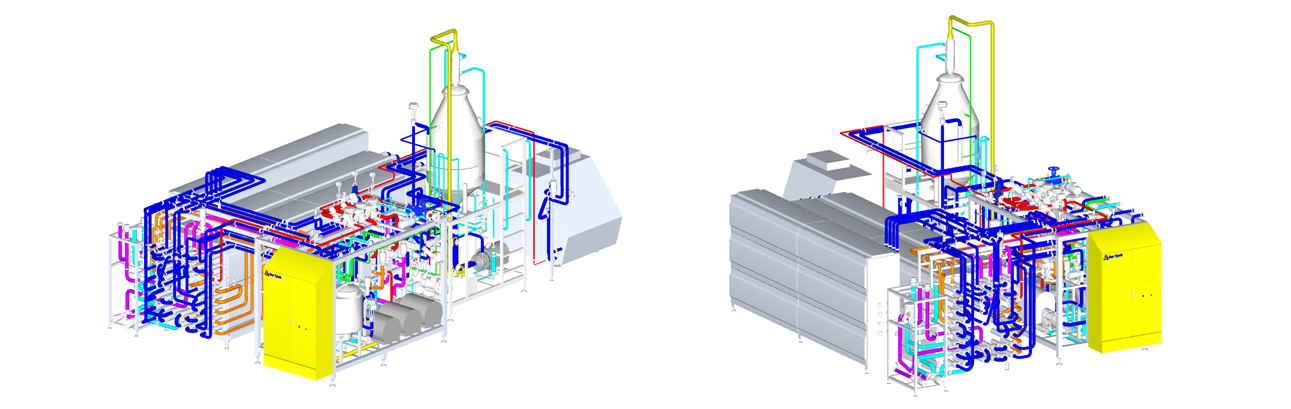

The customer need a UHT module with a production capacity of 8 tons per hour.

Project Solution:

According to customer’s request, we provided a UHT module with following features:

▶ Safety, Stability

ü Leakage proof design, to avoid the mixture risk of products and media.

ü Top quality components to ensure the operating stability.

ü The procedure to ensure the stability of process control is highly improved.

ü Optimized electrical cabinet design ensure the control system stability.

▶ Cost SavingQ

ü Save energy.

ü Extended continuous production time.

ü Prolong service life of components.

▶ Real-Time Data Monitoring

ü Real-time online monitoring of Sterilization temperature and holding time.

ü Real-time online record of concentration, cleaning time and other CIP parameters.

ü Operating history monitoring and record.

ü Parameter modification monitoring and recording.

▶ Remote On-line Trouble Shooting

ü Remote login and troubleshooting via Internet access.

Our UHT module provides a platform for processing of dairy, beverage, yoghurt drink, plant protein drinks for various applications with tailor-made temperature range.

Project Outcome:

Through this project, we have not only earned the trust of key dairy companies in Russia, but also demonstrated our technological and R&D capabilities in processing equipment to all customers in the Russian market.