Project Feature:

☑Customization □Flexibility □Integration □Empowerment □Cost-Efficiency Optimization

Project Background & Requirements:

A high‑volume dairy plant in Eastern Europe needed to eliminate manual handling at the cold‑chain end of a single‑format Aseptic Carton “Flex Base” line running ≈116 packs min‑¹ (≈11 pallets h‑¹). The brief required a compact, fully automatic palletising cell—including stretch‑wrapping—that could be dropped into the existing footprint without disrupting upstream production.

▶ Requirements (extract)

Passport speed of the packaging line = 116 single packs/min;

Weight of single pack = 1090 g;

Number of single packs in a group pack = 12 pcs; Number of group packages in a pallet: 52pcs.

The average speed of product exit from the line coincides with the rated speed of the

filling line and is 9,6 group packs/min, or 11,15 pallets/hour;

The instantaneous speed of product exit from the line exceeds the rated speed of the filling line and can be adjusted within the range from 116 to 118 group packs/min, or from 11,15 to 11,34 pallets/hour.

The products exit the line in the form of 1 group package; Group packages exit the line with the long side first; Cardboard interlayer – required.

Project Solution:

▶ System Components

Depalletizer (automatically feeds empty pallets)

Case organizer & conveyors (chain + roller)

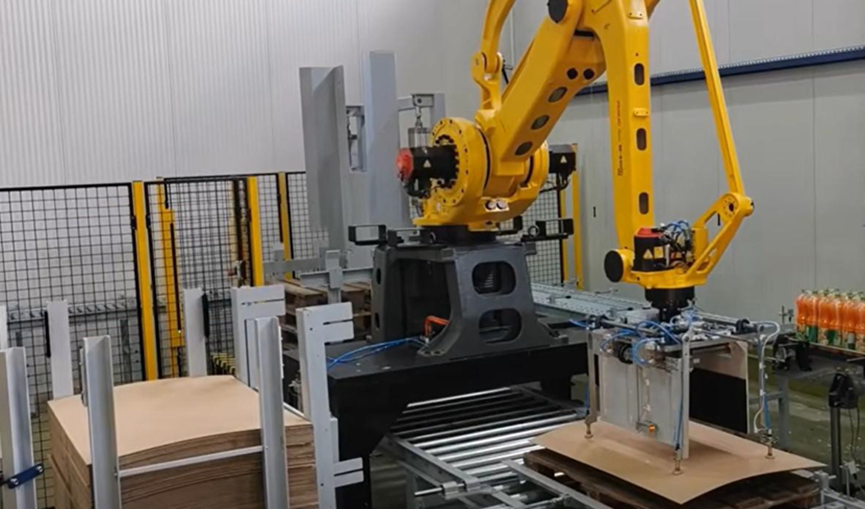

Robotic palletizer (KUKA 6-axis, 70kg)

2-in-1 gripper: carton grabbing + sheet suction

Stretch wrapper (rotary type)

Safety fencing with interlocked doors

Electrical system (PLC + HMI touchscreen)

▶ Working Process

Depalletizer places pallet → robot places interlayer sheet

Picks 2 cases at a time (1 for the last box), palletizes in staggered layers

Builds 4 layers → transfers stack to stretch wrapper

After wrapping, rotates 90°, moves to exit, forklift removes the stack

Project Outcome:

Our proposal won the tender ahead of multiple international competitors. The line was under production.

It is purpose‑built to match the plant’s exact pit size, line speed and layout—using a dual‑mode gripper and an ultra‑compact footprint.